Difference of polyurethane and stone wool panels

Sandwich panels, widely used in the construction sector, occupy a special place among the products produced by UPS Azerbaijan.

The sandwich panels produced by the company are made of environmentally friendly materials and are distinguished by their high quality. In addition, sandwich panels have a high insulating capacity, they are sound and moisture-proof, corrosion-resistant. Sandwich panels are used in the construction of partitions, walls or roofs.

There are two types of sandwich panels produced by UPS. Among them are polyurethane and stone wool panels. But what are the features and differences of these two types of panels?

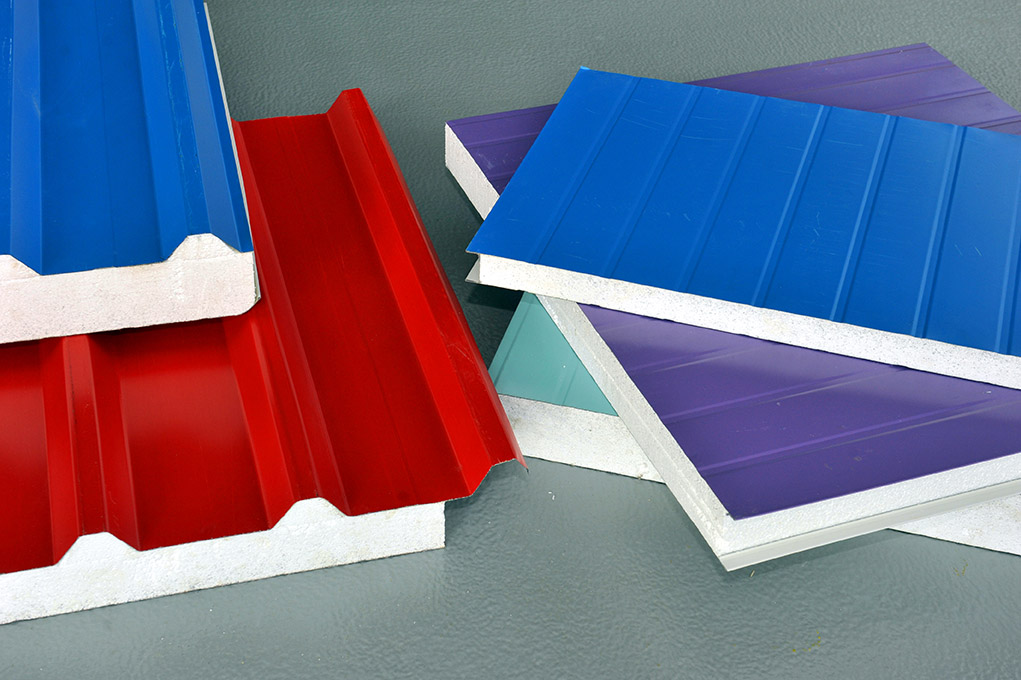

So, polyurethane panels consist of a solid polyurethane foam formed as a result of a chemical reaction. As a Material, foam provides a high degree of thermal insulation. This material does not absorb water into itself and does not sink in water. In terms of temperature, it is resistant to temperatures of 100-110°C. And at higher temperatures, it already loses its properties. The maximum temperature indicator suitable for the use of the material is 70-80°C.

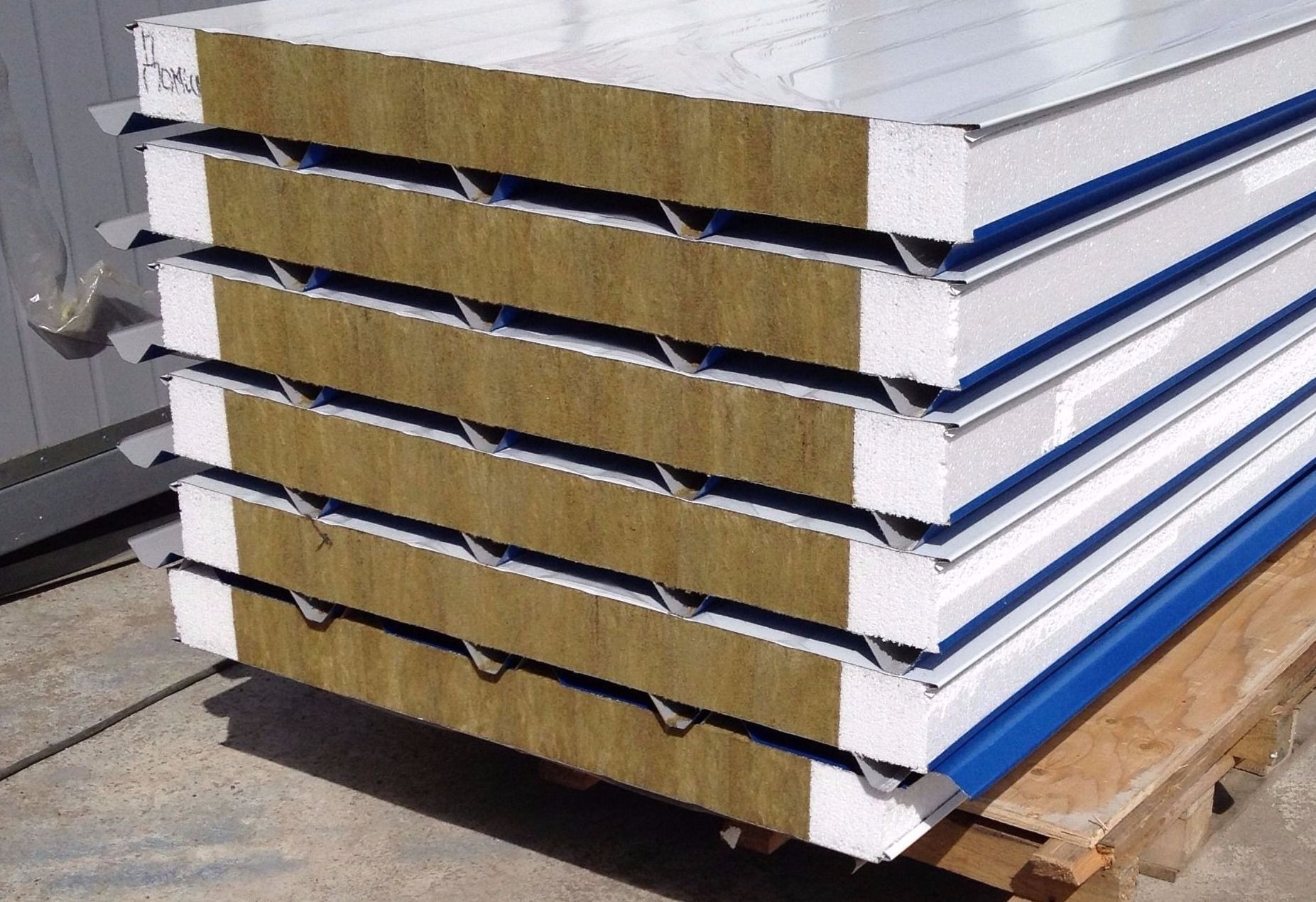

Unlike polyurethane, stone wool panels are created by melting inorganic raw materials, turning them into fibers. The Material is quite durable and, even, does not change in its dimensions when exposed to moisture and dampness. Stone wool panels do not rot, do not mold, do not rust, do not corrode, are not destroyed by insects and microorganisms. Another feature of stone wool panels is that they provide heat and sound insulation, acoustic regulation and a high degree of fire safety.

For a consultation, you can contact the team of professionals of UPS.

Blog

Subscribe to our newsletter